What We Can Do

Thickness Testing

Coating Thickness Gages for Non-Metal Substrates

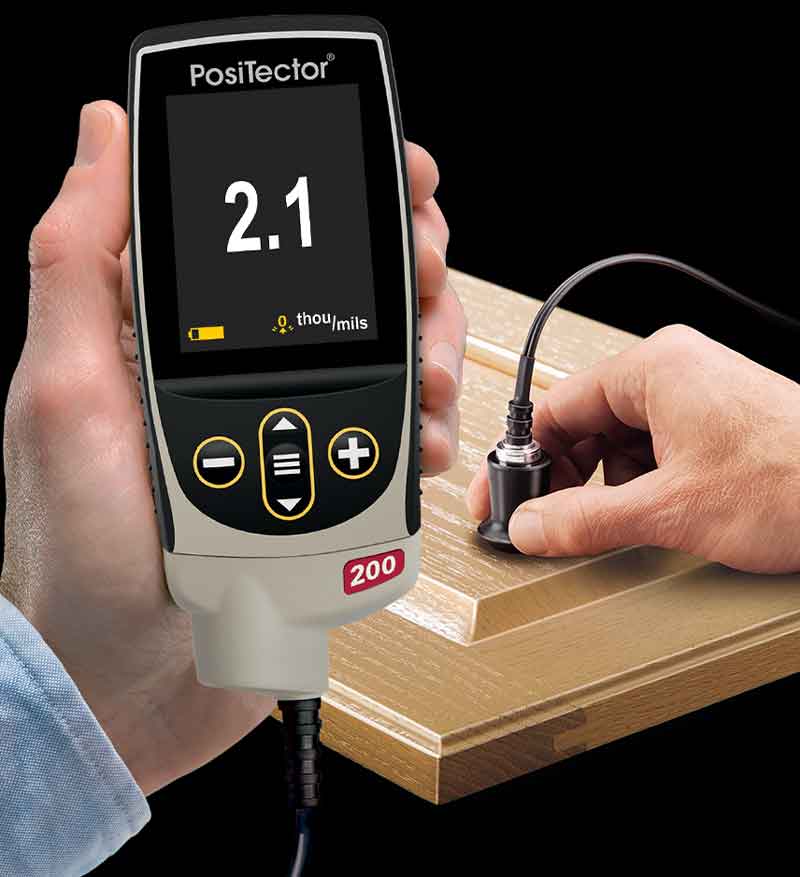

PosiTector 200

Concrete coatings thickness measurements are commonplace in industrial and commercial, especially measuring the applied thickness of waterproofing membrane. Specifications usually call for a minimum membrane thickness. We generally supply the PosiTector 200C or the PosiTector 200 D probe options for measuring the thickness of waterproofing membranes.

- The Positector 200, also known as an Ultrasonic Film Thickness Gauge provides a non-destructive means for determining coating thickness on concrete or similar substrates.

- Reliably measures up to 10mm of waterproof membrane thickness on concrete substrates

- Similar substrates include: Drywall / Plasterboard, cinder block, concrete block, brick, and other cementitious substrates

- Using state of the art ultrasonic technology, the Elcometer 500 can accurately, repeatably, reliably and non-destructively measure coatings, from 150µm up to 10mm thick.

- Fast, accurate & repeatable readings

- Robust, ergonomic design; inspect all day, every day

- Can be used in accordance with ASTM D6132, SSPC PA9 & ISO 2808

How Does PosiTector Work?

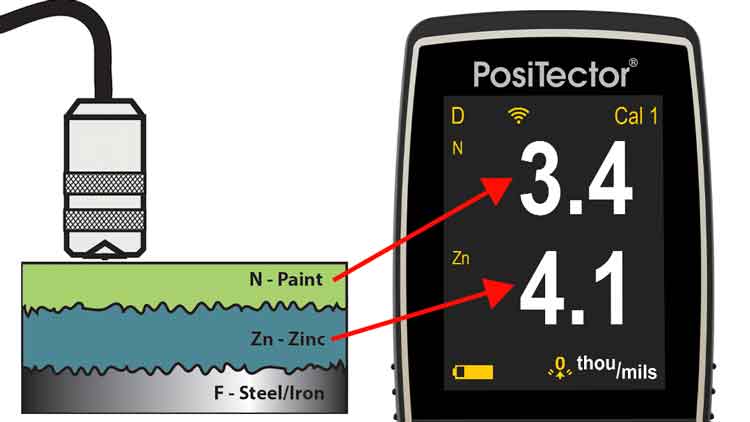

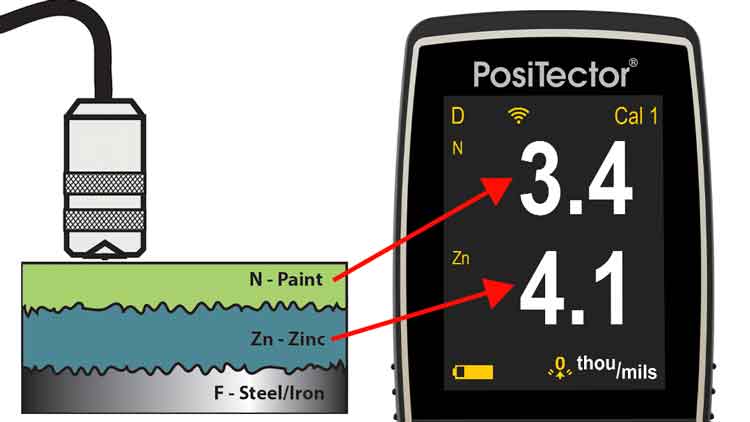

The PosiTector devices are highly sophisticated, utilizing various physical principles like ultrasonic waves, electromagnetic induction, and eddy current technology to accurately measure coating thickness and other material properties. The detection system within these devices works by detecting the interaction between the sensor and the substrate material, then processing this data to provide a precise measurement of the material’s characteristics.

Positector is a fast, easy to use solution for all your management and quality testing needs, preparing professional inspection reports at the click of a button.

What we include:

- Date and time stamped readings

- Statistical and Limit values

- Readings above high limit

- Run charts & histograms

- Batch and gauge information

- Calibration information of pre-programmed materials.

- Store live readings directly to a mobile device and save them into batches

- View graphs in real-time whilst carrying out the inspections.

- Add photographs of the test surface to each individual reading.

- Plot individual readings on to a location map, photograph or diagram via GPS

- Inspection data can be transferred from mobile to PC for further analysis and reporting

- Generate instant .pdf2 report for submission

Proven non-destructive ultrasonic technique conforms to ASTM D6132 and ISO 2808

Thickness Testing

Non-destructively measures a wide variety of applications using proven ultrasound technology.

Apply a small amount of couplant

Place the probe FLAT on the prepared surface, pressing down firmly. The gauge emits an ultrasonic pulse into the coating.

The PosiTector 200 automatically calculates the thickness based on the time it takes for the ultrasonic pulse to reflect from the coating/substrate interface.

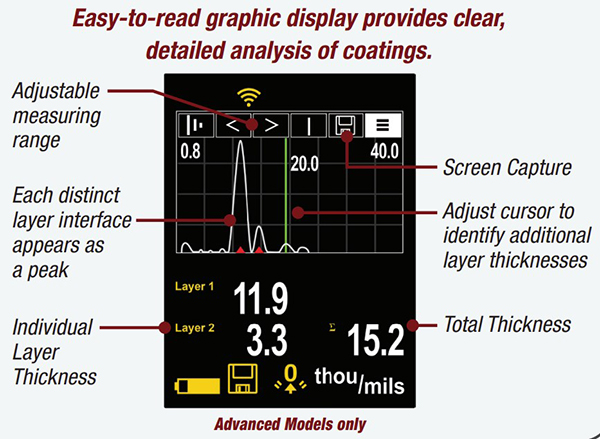

Measuring Layers

For Advanced Models